What is Progressive Cavity Pump?

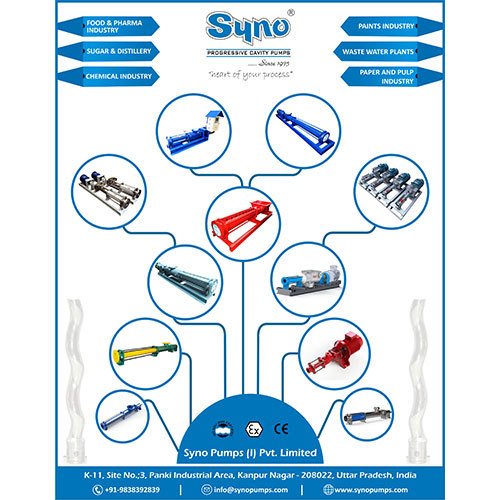

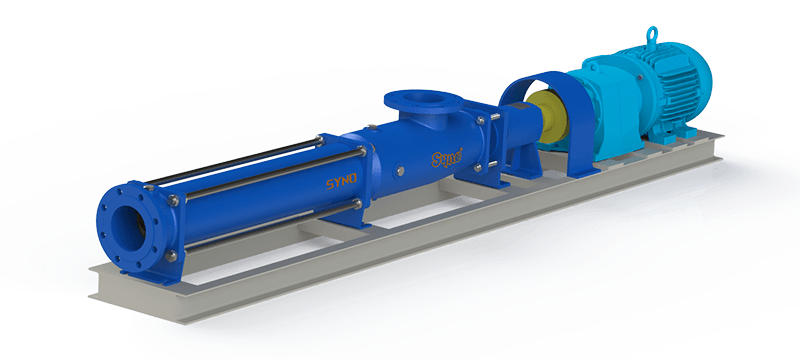

Syno-PCP Pumps is one of the leading manufacturer, supplier and exporter of progressive cavity pumps. Syno Progressive Cavity Pump consists of a helical rotor, which turns inside a helical stator. The stainless steel rotor is machined to a high degree of precision, and the stator is moulded in a resilient elastomer. When the rotor turns inside the stator, a double chain of watertight cavities are created along the axis of the pump. This allows the product to be transferred from the pump intake to the pump discharge shear sensitively.

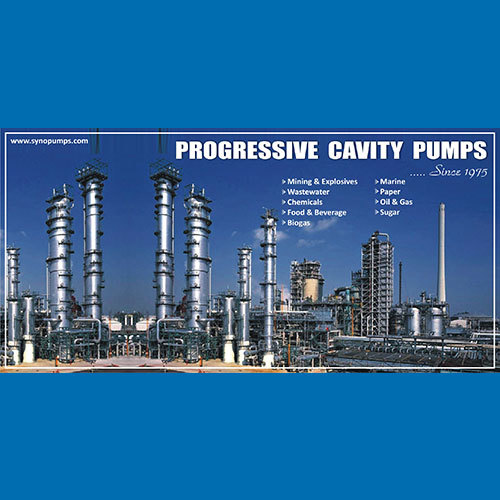

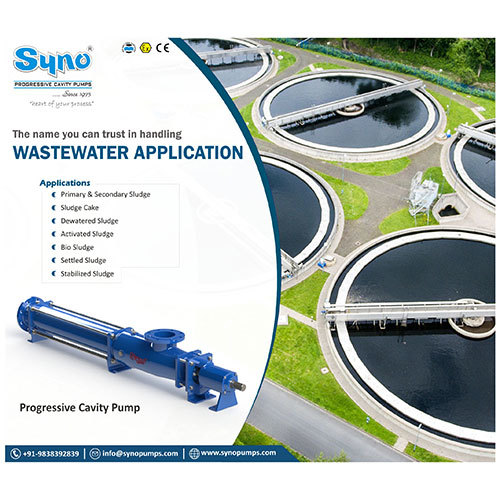

A progressive cavity pump is a type of positive displacement pump used to move fluid through a pipe system. Progressive cavity pumps are known for their ability to handle viscous and abrasive fluids with high solid content, making them suitable for various industries such as oil and gas, wastewater treatment, and food processing. They provide a continuous and pulsation-free flow, making them ideal for applications where a consistent flow rate is essential.

Features & Benefits

01 Viscous & abrasive fluids

It is an old saying in process industry.. where general pumps fail, progressive cavity pumps come into play! Its low internal velocity design means that viscous fluids and those containing solids can be handled effectively e.g. sewage, slurries, waste water and food waste. In addition, the stator has some flexibility reducing the wear particles cause as they come into contact. This is this reason why a Syno Screw Pump is often selected over centrifugal pumps; a design most suited to water or fluids with a similar thickness, or vane and gear pumps that would simply clog with the presence of solids due to their close tolerances.

02 Smooth, low pulsating flow

As the fluid progresses through the overlapping cavities steadily at a known calculated rate, the progressive cavity design benefits from low pulsation pumping. This smooth operation means that in dosing applications, extremely accurate metering can be carried out. Less pulsations in the flow of fluid also limits the amount of stress the other components in the installation are put under.

03 Low shear operation

Thanks to the low internal velocity compared to other pump designs, the progressing cavity pump results in low levels of shearing being applied to the pumped medium. This makes it ideal for handling shear sensitive products that need to maintain their structure during the pumping process. Examples include food products such as chawanprash, grapes etc. Another example of shear sensitive products are thixotropic fluids; those that are thick when static but become less viscous when shaken, agitated or stirred e.g. tomato ketchup, and rheopectic; those that when agitated become thicker e.g. cream. Thanks to their low RPM and gentle pumping motion, progressive cavity pumps keep agitation of the pumped medium to a minimum.

04 Constant flow

As a progressive cavity pump is able to produce the same flow rate regardless of the viscosity of the medium being pumped, they are an ideal solution for when a constant flow is required but the thickness of the fluid may be variable.

05 High pressures

High pressures can be achieved with eccentric screw pumps, ensuring that even difficult to pump fluids can be pump over considerable distances or pressures.

06 Great suction lift capabilities

The Progressing Cavity Syno Pump design benefits from a low Net Positive Suction Head, which means that less inlet pressure is required for the pump to operate at the required duty point. Consequently, they are a good solution when the suction conditions of an application are not ideal.

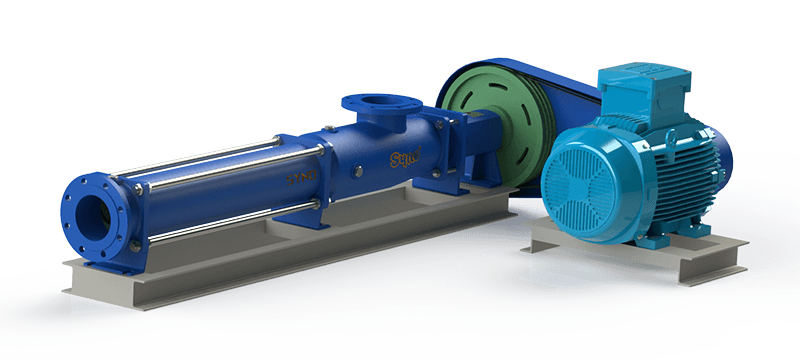

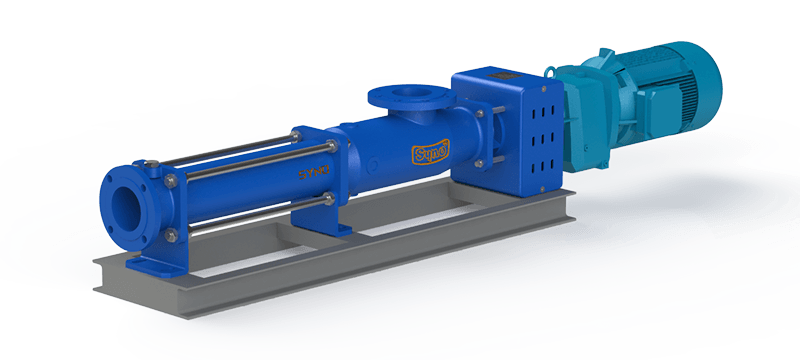

Syno Direct Drive Pump Arrangement

Syno Close Coupled Pump Arrangement

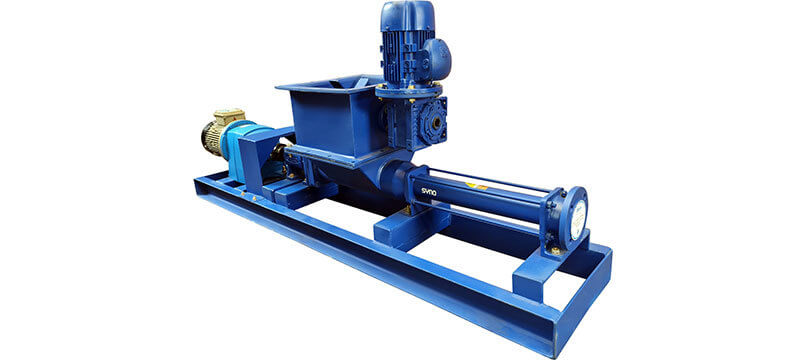

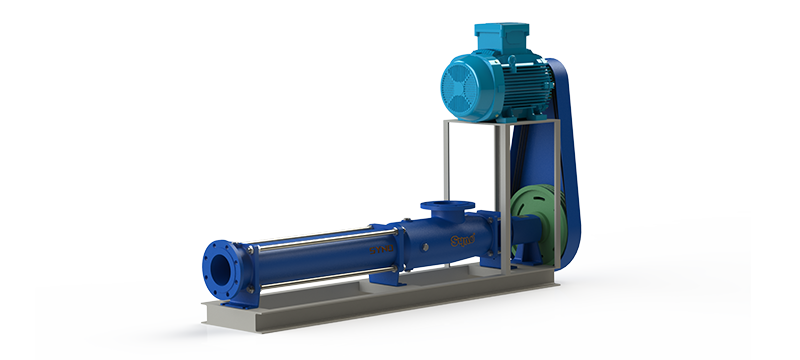

Syno Pulley Drive Overhead Type Arrangement